By Mike Nicklas, FAIA October 21, 2013

Solar thermal collectors installed on the roof of the south wind provide heat for the facility's radiant floor-heating system. The system also supplies a 50-ton Thermax Absorption Chiller, the first solar cooling system in any higher-education facility in North Carolina.

Haywood Community College’s objective from the start was to facilitate and showcase its internationally recognized creative arts programs in a building that demonstrated sustainability.

But such a building has intense energy and water demands and air-quality challenges. Success for this Western North Carolina college hinged on developing creative solutions to those challenges.

Despite curriculum-required equipment loads projected to consume half the building’s energy, extended hours of operation and a difficult site for solar access, we aimed to reduce energy usage at least 60 percent below that of a conventional building of similar size and function, commensurate with Architecture 2030’s objectives.

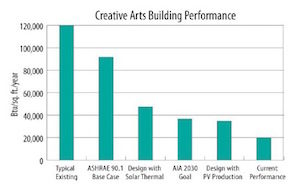

With similar facilities consuming 120,000 Btu per square foot per year and ASHRAE 90.1 standards for new buildings requiring 91,602 Btu per square foot per year, that meant our challenge was to reduce consumption to 36,000 Btu per square foot per year or less.

We set a high bar for sustainability, as well, targeting LEED Platinum accreditation. Among the challenges we’d need to overcome were high water demands, extensive runoff from the rest of the campus, and the air-quality and energy challenges posed by pottery kilns, glazes, paint and welding booths, wood shop equipment and an array of power tools. Even for a firm like ours, with a long track record of energy-efficient, environmentally sensitive architecture, it was a daunting challenge.

Innovative Design and our partners used an integrative design process, surveying the staff, faculty and students and analyzing more than 120 survey responses. We evaluated our sustainable options based on life cycle cost analysis and performed extensive energy modeling throughout the design.

The resulting Creative Arts Building, opened March 1, reflects the arts and is aligned with the state’s new energy guidelines and the college’s strong sustainability focus, according to Dr. Rose Johnson, president of Haywood Community College at the time of the project design, as well as a member of the national steering committee for the Presidents’ Climate Commitment and co-leader of the North Carolina Community College System’s initiative to develop and promote sustainability. “By merging diverse and sometimes conflicting design, programmatic, administrative and fiscal objectives, the facility serves as an example of sustainability in action,” she said.

In just the first four months of operation, energy consumption at the building was outperforming projections, with levels on track to be as low as 19,640 Btu per square foot per year. The Creative Arts Building is expected to be the first LEED Platinum Higher-Education classroom/ lab building in North Carolina.

Form Follows Function

The 41,000-square-foot (3,800-squaremeter) facility, including 35,486 square feet of air-conditioned space, was designed to accommodate the college’s growing clay, jewelry, wood and fiber programs for full-time and nighttime continuing education students.

The facility consists of three levels stepping down a heavily wooded, south-facing hillside. We arranged the four major studio spaces by wing and floor level so that each has access to ground-level entry. This key design decision enabled the entire facility to be optimally oriented for solar access, provided excellent daylighting and natural ventilation in all of the main studio spaces and retained as many of the existing trees on the site as possible.

By employing a design that conformed to the site, we were also able to place, within each of the lower two floors, the main studio space on the south side of the wing and less-used support and storage spaces on the north, fully bermed wall.

The programmatic needs of each studio, classroom and office space, along with the varying types of equipment and materials used within each space, dictated the type of energy, water and indoor environmental-quality solutions we employed.

Within the clay studio, for instance, the need for eight electric kilns and three gas kilns dominated solutions to energy consumption and comfort. The use of toxic glaze chemicals dictated that we take extensive measures to address air quality.

The jewelry program had kilns as well as soldering booths and, because students do close-up, detailed work in the studio, enhanced lighting levels were critical.

The wood studio contained numerous table saws, planes and drills in addition to paint booths, all necessitating extensive ventilation and dust-collection systems. Because of the dangers associated with operating the equipment, the room called for elevated light levels and minimized glare.

The fiber studio had less energy-intensive equipment, but work at the looms required high light levels. We focused on good ventilation strategies in the dye room, as well as in the main studio spaces, where small fibers could easily become airborne.

The climate presented different challenges. Haywood County is located in the mountains of Western North Carolina, just west of Asheville.

While the average annual temperature is 55°F (13°C), temperatures have ranged from 100°F to -16°F (38°C to -27°C). From purely a degreeday perspective, heating outweighs cooling by a ratio of 85 to 15 percent. However, with the extremely high internal loads within the Creative Arts Building, the actual demand for supplemental energy shifts to 60 percent for heating and 40 percent for cooling.

Design and Construction Team

The design team consisted of the Raleigh, N.C.-based architectural firm of Innovative Design, Elm Engineering, B&F Consulting and Landis Inc., all signatories to the American Institute of Architects’ 2030 Commitment — a goal to have all new U.S. buildings achieve carbon neutrality by the year 2030. Miles-McClellan Construction Co. was the general contractor, and Bill Dechant was Haywood Community College’s director of campus development.

Efficiency, Orientation Lead Energy Strategies

Our energy-saving strategies in the facility focus on efficiency, passive heating and cooling, natural daylighting, solar heating and cooling, and photovoltaics.

Energy Efficiency

Logically we started with addressing energy-efficiency. Creating a highmass, well-insulated building shell provides storage benefits, as well as increased comfort and durability. The exposed interior walls and floors were important for retaining thermal stability in that many spaces required high levels of ventilation. The berming of the two lower wings, through ground coupling, also provided significant thermal benefits.

High-performance, low-e glass is employed for all the lower view windows, while upper daylighting aperture selection was dictated by orientation (south or north) and the functions occurring within each space. We selected thermally broken door and window frames to improve energy efficiency.

Radiant roof loads are minimized through the use of Energy Star metal roofing panels and white membrane roofing, as well as the fact that the majority of the roof was covered with solar panels.

Passive Heating and Cooling

Given the predominant heating load, we implemented south-facing glazing strategies to maximize daylighting and passive heating benefits. We placed lightshelves immediately beneath the daylighting glazing and above the view glass on the south. This strategy both enhances daylighting and helps shade the lower view glass in the warmer months.

In order to maximize natural ventilation, we placed operable windows throughout the facility and incorporated north-side stack ventilation shafts that extend from the lowerlevel shop areas to high above the secondfloor levels. These shafts allow for both fan-assisted and natural ventilation options with outside air entering through the operable windows, rising through the shafts and exiting high above the rooftop.

Daylighting and Lighting

More than 85 percent of the facility’s regularly occupied spaces are designed to provide superior daylighting levels for two-thirds of the daylit hours.

We selected the types of daylighting based on the expected conditions in the various spaces. These spaces would routinely be dirty and house potentially dangerous equipment. Students would need high light levels (75 to 100 footcandles in some locations) with minimal glare for safety’s sake. Based on these needs, we selected fiber-filled Solera glazing, because it effectively filters the sunlight, minimizes cleaning issues and provides the added benefit of improved conductive performance.

Within the main display gallery, as well as in the multipurpose classroom spaces, we employed roof monitors with clear glazing to minimize the sizes of the apertures and interior baffles to reduce glare. Located on the top floors of their respective wings, the clay and fiber studios incorporate high, north glazing to provide excellent controlled light.

”One of the keys to the project’s success was the early decision to step the building down the south-facing, sloped site using east-west oriented wings that house the different programs and maximize solar access.”

— Masaki Furukawa, AIA, project architect, Innovative Design

To control supplemental light levels in all of the daylit spaces, we use daylighting sensors, which automatically dim the energy-efficient light fixtures, adjusting the light levels to meet the needs of each space.

Solar Heating and Cooling

The 152 29-square-foot (2.69-square-meter) Schuco Premium U.5 DG solar thermal collectors installed on the roof of the south wing provide heat for a radiant floor-heating system that extends throughout the facility. Additionally, this same solar system supplies 200°F (93°C) water to a 50-ton Thermax Absorption Chiller. The solar cooling system is the first to be employed in any higher-education facility in North Carolina.

A vertical, 15,000-gallon Highland thermal storage tank is located outside and immediately adjacent to the main mechanical room, which houses the absorption chiller as well as two electric chillers. A gas boiler provides backup heating, and if solar energy for cooling falls short, the electric chillers are activated.

A closed solar loop is protected from stagnation by diverting flow from the solar loop to the same cooling tower utilized by the chillers. In the event of an unscheduled power failure during ideal collection times, a backup generator continues the flow within the solar loop, and cold municipal water is allowed to flow to a heat exchanger in the solar loop that cools the col- lectors. The municipal water, in turn, is routed into the rainwater-harvesting tank in order to conserve the water.

Solar Water Heating

Seven AET AE-40 collectors, coupled with a 400-gallon storage tank, provide most of the facility’s domestic hot water needs.

Photovoltaics

A 112-kilowatt (kW) peak photovoltaic system consumes the majority of the remaining roof area. A total of 468 Suniva ART 245 photovoltaic modules generate power that will initially be directed back into the utility grid.

Additionally, the Creative Arts Building has small PV systems for two emergency call stations and a 1.6-kW dedicated rooftop array that powers a recirculation pump treating runoff water in the constructed wetland.

Solar Lease Improves Project Economics

We achieved the biggest bang for our buck by integrating day lighting and energy-efficiency strategies. However, by engaging a solar developer in the $8.8 million project, the college was able to achieve a net level of energy consumption seldom seen in public buildings in North Carolina, while still remaining financially viable.

Selected through a competitive solicitation, Asheville-based FLS Energy owns, operates, maintains and finances not only the 112-kW photovoltaic system, selling the power produced to Duke Energy Progress, but also the solar systems providing space heating, absorption cooling and water heating directly to the facility. This approach, all implemented through private financing, enabled Haywood Community College to reduce its operating costs from day one. More importantly, the college has the option to purchase the systems in six or seven years, when the revenue derived from the energy savings will be significantly greater than the expense associated with the purchase and long-term maintenance.

Sustainable Approach Extends to Site

Other green features include environmentally sensitive materials and finishes, native planting, efficient lighting, natural ventilation and a storm-water management strategy that employs bioswales and a constructed wetland to capture and treat runoff. The vegetation in the bioswales and constructed wetland is planted to capture nitrogen and filter the runoff water before it reaches the local mountain streams.

We chose low and no-VOC paints, sealants, adhesives and cabinetry to create a healthier environment for the building’s occupants. The studio exhaust systems incorporate an extensive heat-recovery system to ensure adequate fresh air with minimal heating or cooling losses.

The radiant floor system, predominantly supplied by solar-heated water, was a logical choice due to the high ventilation rates in the studio areas. In addition to the 15,000-gallon solar tank, the massive floors into which the radiant floor piping runs add significantly to the overall thermal capacitance of the building.

A rainwater harvesting system, which collects rainwater from the roof and stores it in a 25,000-gallon underground tank, will annually save the community college more than 570,000 gallons of potable city water. The rainwater is UV-treated and mainly used for toilet flushing and water make-up in the cooling tower, saving more than 90 percent of the building’s overall demand.

In addition to dealing with runoff from areas immediately surrounding the Creative Arts Building, runoff from 3.45 acres of Haywood Community College also funnels through the building site. More than 90 percent of the immediate site runoff, plus the runoff from surrounding areas, is treated by two sand filters, a constructed wetland pond and a bioswale. The net effect of the project is that there is less runoff than before the project was constructed.

A 1.6-kW photovoltaic array tied to a DC pump, mentioned earlier, moves water from a lower retention area at the outfall of the wetland pond to the top of a waterfall that leads back into the wetland pond. Specially designed soils and a variety of aquatic plants help reduce pollutants from the storm- water runoff.

Energy Performance Beats Projections

Collectively, these building-integrated approaches to renewable energy and energy-efficiency were projected to reduce energy consumption 38 percent versus a new code-compliant building (ASHRAE 90.1), and 29 per- cent versus similar existing facilities in the region.

However, based on detailed energy monitoring results from the grand opening on March 1 through July 1, the actual performance of the building is even better. Despite commissioning just being completed in June, the sub- system monitoring has indicated that electrical consumption is 24 percent less and natural gas consumption 79 percent less than predicted for a typical year.

However, based on detailed energy monitoring results from the grand opening on March 1 through July 1, the actual performance of the building is even better. Despite commissioning just being completed in June, the sub- system monitoring has indicated that electrical consumption is 24 percent less and natural gas consumption 79 percent less than predicted for a typical year.

For more information on the Creative Arts Building, see tinyurl.com/creativeartsbuilding.

Mike Nicklas, FAIA, is president of Innovative Design (innovativedesign.net). Innovative Design was founded in 1977 and since its inception has focused on creating energy-efficient, environmentally sensitive architecture. Specializing in educational buildings, the firm has been engaged in the design of more than $2 billion in higher education and K–12 facilities. Over the past 36 years, its 4,755 green buildings have collectively saved clients $139 million in energy bills, reduced their city water consumption by 295 million gallons and reduced peak utility demands by the equivalent of a 127-mega-watt power plant.