By Mick Sagrillo October 27, 2013

Guyed lattice and freestanding towers must be climbed in order to inspect and service a wind turbine. Climbing comes with the risk of falling, and of dropping tools or parts that can injure anyone foolish enough to linger around the tower base (most likely a co-worker). Guyed tilt-up towers that are lowered to grade rather than climbed were developed as an alternative to climbable towers. After all, what can be safer than working at ground level? Guyed tilt-up towers, however, come with their own risks.

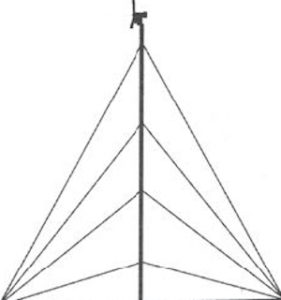

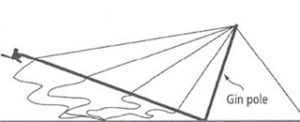

Guyed tilt-up towers are complex structures that are very stable once vertical and secured, but extremely unstable during raising or lowering. It takes a crew of more than two, the minimum needed to work on a climbable tower, to safely raise or lower a guyed tilt- up tower. Since a lot is going on simultaneously, it is not uncommon to position a worker at each side guy anchor, at the gin pole anchor with the winch and at the center tower anchor.

This checklist assumes that you need to lower a guyed tilt-up tower to inspect the turbine and tower, and builds on last month’s column: Before Climbing That Tower.

This checklist assumes that you need to lower a guyed tilt-up tower to inspect the turbine and tower, and builds on last month’s column: Before Climbing That Tower.

- Depending on the system, brake the wind turbine so that the rotor doesn’t turn.

- Turn the power to the tower off.

- Inspect the concrete foundation and anchors for cracks and rust.

- While at the foundation, examine the ground rods and wires to the tower. Tighten any loose connections.

- Look closely at the guy attachment hardware, turnbuckles and especially the condition of the guy cables where they pass around their guy thimbles. You do not want to tilt a tower if the guys are frayed or rusting or if strands are broken. Slipped cable clips indicate a serious problem. Are the turnbuckle figure-8 safeties secure?

- Check the junction box for insects and spiders. Be especially cautious of wasps.

- While at the j-box, check the above-grade flexible conduit to the tower to assure it is not coming apart or cracked and leaking.

- From the base of the owe, visually check all guy stations up the tower. Binoculars come in handy for this. Look for anything that seems to be amiss and that could cause problems while lowering the tower.

- Note the wind direction and how it will impact the lowering process. If winds are strong enough to move the tower even a bit, it may be prudent to wait for calmer winds.

- Read and re-read the manufacturer’s tower-lowering procedure and precautions.

- Make sure that everyone on the crew understands all aspects of what is involved. Each person on the crew needs to understand not only their job but everyone else’s job as well. A pre-lowering “pow- wow” is essential, even with an experienced crew. Each installation and location is different. Many eyes make for a safer job.

- Make sure that you have an excellent system for communicating among crew members. In addition, authorize any crew member to halt the lowering if she or he sees something amiss or doesn’t understand what is happening.

- All crew members must be “on the job” during lowering. Most mistakes that have occurred while lowering a guyed tilt-up tower were due to crew members chatting or simply not paying attention.

- After securing the lowering winch, hardware and cables, have another crew member double-check this assembly. Once the tower is being lowered, there’s no going back to re-attach or re-adjust something that was assembled incorrectly.

- Once the tower is disconnected from the “lifting” anchor and the winch is deployed, it is incredibly unstable until completely on the ground. A falling tower accelerates at 32 feet per second squared (acceleration due to gravity). A loose tower can fall to its destruction in a fraction of a second.

- The direction that the tower is lowered in is the most dangerous area to occupy, so make sure no one is in this “fall zone” unless necessary. If someone must be there, the crew must watch what is happening very closely.

- Take your time lowering the tower. As it approaches the ground, it doesn’t necessarily get more stable. The forces on the lifting cable and winch increase to their maximum as the tower moves to a horizontal position.

- Block the tower up so that it comes to rest securely, but off the ground. You don’t want to damage the wind turbine by resting it on the ground. In addition, the tower now has an “underside,” and you will need clearance to inspect the guy cables, hardware and attachments there.

- Never duck under a blocked-up tower to get to the other side. It may be a pain, but walk around. Towers have been known to shift and fall.

- Once the tower is down and secure, pull out the wind turbine manual and give the turbine and all things electrical a thorough inspection.

- As with climbable towers, take notes and digital photos to record the maintenance of the tower and turbine. The records become invaluable references and serve as a guide to similar installations that you may service in future.

Mick Sagrillo (msagrillo@wizunwired.net) teaches and consults about wind power, and has powered his home with wind power since 1982.